Catalog

Hotline

+86-510-87876970

+86-510-87877260

PRODUCTS

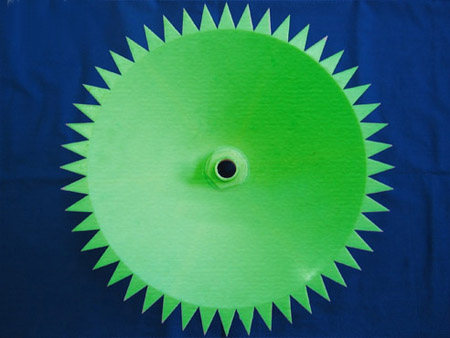

Dispersed fluidization aerator

Product structure and specifications

Material: glass fiber reinforced plastic

Service area: installed in pushing flow and completely mixed aeration tank, each service area is 0.8 1.5 m2 oxygen filling efficiency: when the depth of 4 m, oxygen transfer efficiency eta = - 8-9%, oxygen filling capacity of 0.3-0.41 kg · oxygen/hour. (a)

Rules: Φ 400, Φ 600

Structure and principle of oxygen filling

1. The structure

Cloth of sawtooth QiTou, structure similar jinshan type I. Air is cutting dispersing effect, D = 100 mm in diameter, height H = 120 mm, serrate at 18.

2. The diffuser cover with a serrated, diffuser cover design inverted umbrella, umbrella in circle of twelve Φ 12 of porosity, rise to fill gas again even the role of the diffuser cover can reduce energy consumption and mix hydrosphere uniform distribution, reduce the diffuser to the requirement of installation levelness. D = 600 mm in diameter, diffuser cover cloth around 60 leaning sawtooth in an attempt to further cut down blisters.

2. The principle of oxygen filling

By the visible and the influencing factors of oxygen transfer rate is mainly: aeration water flocculant actuator, enterprise mix mixed, diameter of bubble size, air quantity and partial pressure of oxygen in liquid phase and so on.

Φ type 600 Dispersed fluidization aerator oxygen filling role mainly consisted of the following:

1. Liquid mixed mixing effect Gas by pipeline to aerator, after Φ QiTou 25 inner hole through the sawtooth cloth, as water cut for the first time. The diffuser cover for the sawtooth again and after cutting, drive around the static water rise, due to energy difference mix mixed gas and liquid, in addition because the aerator bottom, rising bubbles with falling after aeration convection currents occur, and increased the gas-liquid mixed mixing, accelerate the renewal of gas-liquid interface water film.

2. Bubble after two serrated cutting and gas-liquid mixing mixing effect, the smaller the diameter of bubble, thereby increasing the gas-liquid contact area, is advantageous to the oxygen transfer.

3. The spread of the diffuser mask Diffuser cover several out a bunch of gas diffusion into cylindrical, changed the bottom gas state, increases the gas area, and make the bubbles at the bottom of the diffusion and at the bottom of the mixed gas and liquid mixing, is more advantageous to aeration oxygenation.

Dispersed fluidization aerator oxygen filling and jinshan type I difference, lies in the secondary cutting and Dispersed flow, thereby increasing gas range. The flow pattern changed in the pool. With fixed screw has smaller height difference between equipment and gas range big bottom of mixed mixing effect, so it has good oxygen filling performance